Italy

Not just offshoring: the revival of genuine Made in Italy jeans (handmade in Veneto)

We have often become accustomed to thinking of the textile sector as a wasteland of rampant offshoring, where the production of a pair of jeans is synonymous with exploitation in Bangladesh or some remote area of Africa, with starvation wages and “disposable” quality. Yet, for those who still believe in the real economy and the added value of domestic manufacturing, there are exceptions that confirm that Italian know-how is not dead, but has taken refuge in high quality.

This is the case with the Iceman project by Spirit of St. Louis, which has decided to show—without filters and with rare transparency—what it really means to produce jeans in Italy today. We are not talking about a simple final assembly to obtain the tricolor label, but a short, very short supply chain, rooted in the Vicenza area.

This is not a paid promotional article, but simply aims to show how certain things can still be done in Italy, and done well. Just think about buying a product that lasts, that is not just something disposable, for one season, but a durable product, characteristic of the person wearing it.

Back to basics: 1881 and Japanese Denim

The operation is also interesting from a historical and cultural point of view. The Iceman model is a faithful replica of the work pants worn by American pioneers and gold prospectors in 1881. A garment that had to be indestructible out of necessity, not for fashion. To replicate that robustness, the choice fell on a heavyweight Japanese denim (known to purists as the best in the world), but worked entirely by Italian hands.

A ten-minute documentary video, which is decidedly long by the frenetic standards of social media but necessary for those who want to understand the technique, reveals the production process. There is no magic, just craftsmanship. And true craftsmanship takes time.

The complexity hidden in the details

Analysis of the production process reveals why a handcrafted garment cannot cost the same as an industrial one. The manufacturing stages follow protocols that the fast fashion industry abandoned decades ago to cut costs.

Here are the salient technical characteristics that emerge from production:

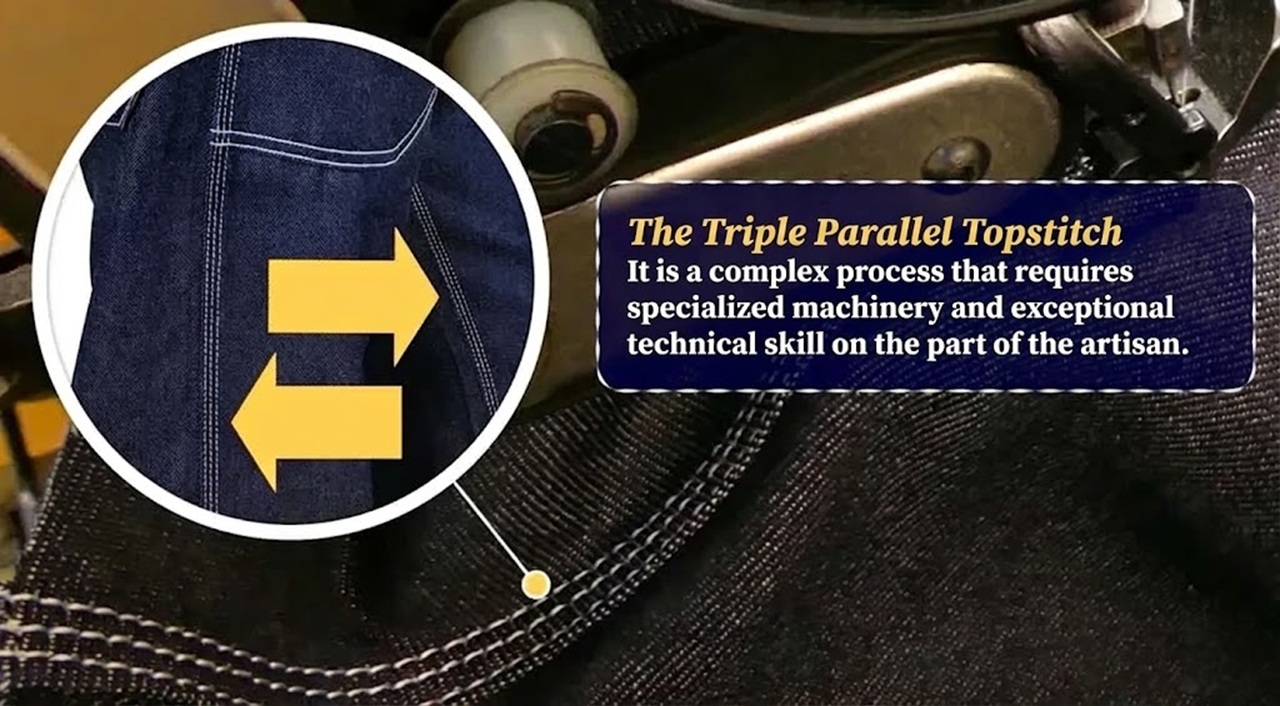

- Triple parallel stitching: This is not an aesthetic detail, but a structural one. It requires specific machinery that can handle thick threads and, above all, operators capable of controlling the tension on heavy fabrics. As an old commercial said, “power is nothing without control”: here, the tailor’s hand is essential.

- Pocket bags and stamping: The pocket bags are made of raw cotton with twisted thread (double or triple). Each piece is cut by hand, ironed individually, and stamped with specially created tools.

- Handling different fabrics: Working with heavy (stiff) denim layered with lighter cottons is an engineering nightmare for those who sew. It requires tension management that a standardised automatic machine struggles to replicate without defects.

- The back cinch: A typical detail from the late 19th century, wide and enveloping, secured with numerous rivets to ensure that the trousers remain in place even under work stress.

The importance of “Travettatura” and the local supply chain

A technical aspect often overlooked by non-experts is travettatura (or reinforcement). These are small, densely stitched reinforcements placed at points of greatest tension: pockets, loops, buttonholes. In the Iceman model, these are doubled compared to the commercial standard. The result is a garment “engineered” to last, not to be replaced after one season.

But perhaps the most relevant factor for those observing the local economy is the knock-on effect. The steel buttons are manufactured and customized in Italy. Labeling, cutting, ironing, and assembly take place within a few kilometers of Vicenza.

We can say that, even before being Made in Italy, this is a 100% Made in Veneto product. In an era of long and fragile supply chains, seeing an example of ‘zero kilometer’ production in textiles is a small but significant victory for quality production over soulless quantity.

Questions and answers

Why do handmade jeans cost much more than industrial ones? The difference lies in the processing time and labor. Industrial jeans are assembled in automated chains, often in countries with low labor costs, using standardized steps. Jeans like the Iceman require manual cutting, individual ironing of each component, the use of specific machinery for high thicknesses and, above all, specialized Italian personnel. The handling of different fabrics (heavy denim and light cotton) and triple stitching require technical expertise that mass automation cannot replicate with the same care.

What does “Japanese denim” mean and why is it used in Italy? Japanese denim is now considered the “gold standard” for jeans enthusiasts, superior in texture and dyeing technique (often natural indigo) to commercial fabrics. Japanese looms often replicate old American shuttle machines, creating a fabric with a unique “feel” and character. Using it in Italy means combining the best raw material available on the global market with Italian sartorial expertise. It is a technical choice to ensure that the garment ages well, rather than deteriorating.

What is bar tacking and what is it for? Bar tacking is a fundamental reinforcement operation in workwear tailoring. It consists of a series of dense, closely spaced stitches, applied to the points of the trousers subject to the greatest mechanical stress, such as the corners of the pockets, the belt loops, and the base of the fly. Without quality bar tacking, the fabric or seams would give way under tension. In the Iceman model, the intensive use of bar tacking and hand stitching serves to make the garment virtually indestructible, restoring the original function of jeans as heavy workwear.