Economy and business

China launches its first gas cooled nuclear reactor

China has started commercial operations of the world’s first new-generation gas-cooled nuclear reactor, state media reported on Wednesday.

According to the state-run Xinhua news agency, the plant in Shidao Bay, in the eastern province of Shandong, is powered by two gas-cooled high-temperature reactors instead of pressurised water, making it more efficient and economical. These are fission reactors, which therefore use the fission of uranium isotopes, although in this case the fuel is specially prepared. It is built by the State Nuclear Power Technology Corporation, SNPTC.

Translated with www.DeepL.com/Translator (free version)

A very innovative modular reactor

Conventional reactors produce electricity from nuclear energy, but these advanced models – known as small modular reactors or SMRs – can be used for other applications including heating, desalination or steam for industrial needs. Their very compact size would allow them to be placed in industrial plants or near urban centres.

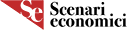

The core of the High Temperature Reactor (HTR-PM) is a new generation high temperature gas-cooled (HTGR) modular reactor with an external diameter of 3 metres and a height of 11 metres Helium cooling. The reactor has intrinsic safety, i.e. in the event of any anomaly, reaction activity ceases, with fourth-generation safety features. China holds the intellectual property rights for the HTGR technology. The

“SNPTC incorporated feedback from the Fukushima power plant accident and designed the reactor with improved safety features and a thermal safety margin of more than 15 per cent.”

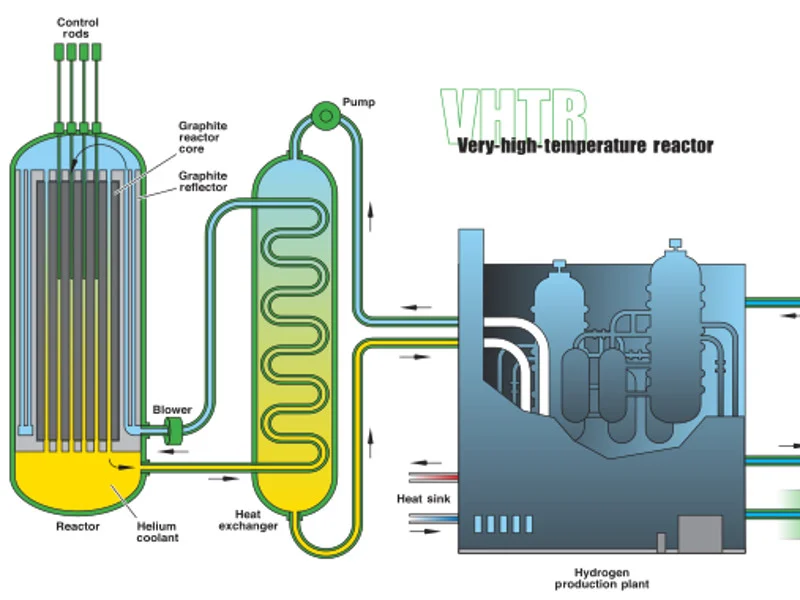

The Chinese-designed reactor uses tristructural isotropic coated capsule (TRISO) fuel, which is expected to provide improved safety. The TRISO fuel design contains tiny uranium particles coated with layers of carbon and silicon carbide (SiC). The SiC layer can retain fission products below 1,600°C.

The reactor uses graphite as a moderator, while low-level helium acts as a coolant.

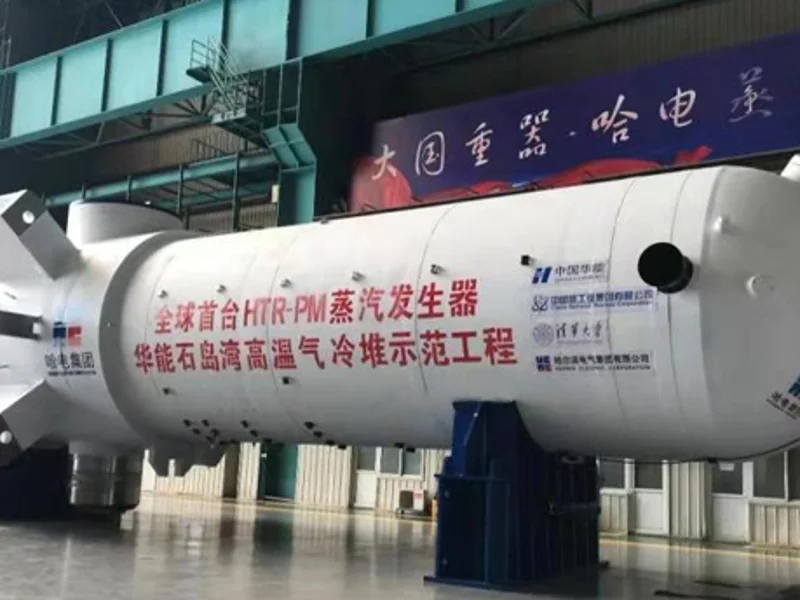

The HTR-PM demonstration project comprises two 250 MW reactors and two steam generators. The reactors have individual primary circuits and shared auxiliary facilities, including fuel handling and helium purification systems.

The reactors have a cylindrical pebble fuel core and independent shutdown systems with a control rod and absorption sphere. The passive waste heat removal system improves the reactor’s safety features.

Over 90 per cent of the equipment at the Shidao Bay plant is of Chinese design, project manager Zhang Yanxu told Xinhua.

Construction of the plant started in 2012 and the first SMR was connected to the power grid in 2021.

According to proponents, multi-purpose SMRs could play a central role in the decarbonisation and energy transition due to their compact and simplified architecture, with their modular design reducing costs and construction time.

According to the International Atomic Energy Agency, more than 80 SMR projects are currently under development in 18 countries.