International

Effects of Taiwan earthquake on Semiconductor and High Tech industry

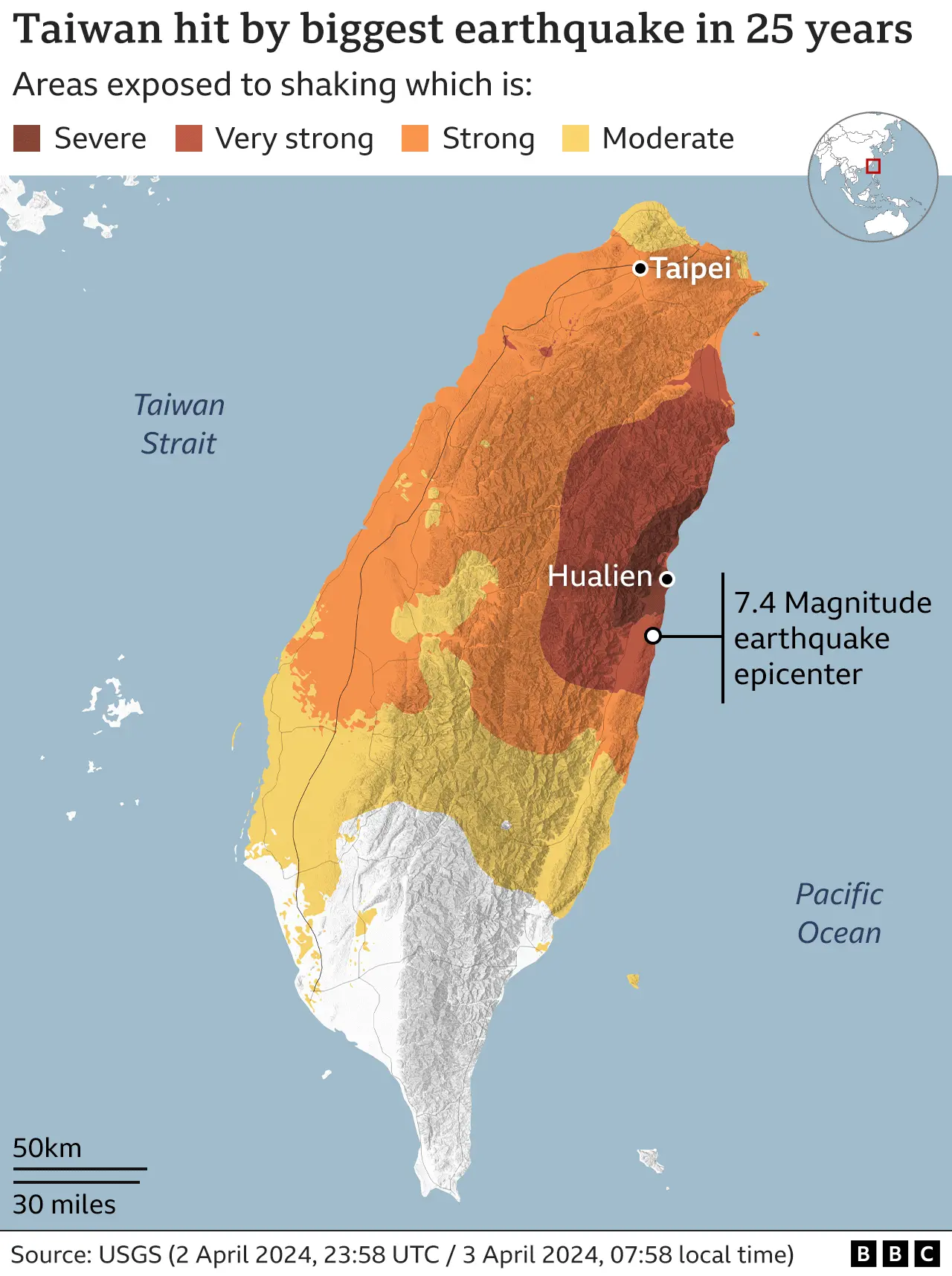

At 07:58 Taiwan time on April 3, an earthquake of magnitude 7.3 occurred in the waters of Hualien County in Taiwan (23.81 degrees north latitude and 121.74 degrees east longitude), with a depth of 12 kilometers; then, a strong earthquake of magnitude 6.5 occurred at 08:11, followed by continuous aftershocks of small magnitude relative to the main one, but always well felt

The Taiwan Meteorological Administration’s seismic center stated that aftershocks of magnitude 6.5–7.0 could occur in the next 3–4 days. This earthquake was also the largest earthquake since the “921 Earthquake” in Taiwan in 1999. Here is the epicenter of the earthquake:

Epicenter of the earthquake in Taiwan (source: BBC)

What impact did the earthquake have on the electronics industry?

Taiwan is home to many major manufacturers, such as TSMC and UMC. For these manufacturers, water and electricity should not be missed for a moment. Once operations are suspended, the costs of reopening would be enormous.

When an earthquake of magnitude 3 or higher occurs, some semiconductor factory equipment activates an automatic protection mechanism to shut down assembly line equipment.

At that time, wafers in processes such as sputtering lose the vacuum environment due to the power failure, causing wafer fragmentation. In addition to wafer damage and scrapping, manufacturers also have to clean up subsequent debris, so wafer damage alone causes a huge loss of production value.

In addition, according to disaster prevention regulations for cleanrooms such as semiconductor and panel factories, if a magnitude 4 earthquake occurs in the factory area, cleanroom personnel must be evacuated to avoid accidents involving gas and toxic liquid leaks.

It is worth noting that in the area where semiconductor and panel factories are concentrated in Taiwan, the maximum earthquake intensity was magnitude 5 in Taichung County and Hsinchu, while the maximum earthquake intensity in Hsinchu City and Tainan was magnitude 4. TSMC, UMC, and Micron all have factories in these areas, so it is to be expected that there would be disruptions in production lines.

Hsinchu Science Park , where TSMC has an office.

According to Hsinchu Science Park, TSMC and Zhunan Liandian have partially halted work; Zhunan Inntron Optoelectronics has also partially halted operations; and employees of Jingyuan Electronics and Tomei Technology have all been evacuated. Hsinchu Science Park panel manufacturer Youda Optoelectronics and semiconductor supply chain companies Wanghong Electronics, PSMC, and UMC are operating normally.

Nanke Park announced that the earthquake magnitude at Inntron Plant B, TSMC Plant 18, and Hanyu Caijing was magnitude 4, and the earthquake intensity at Inntron Kaohsiung Plant F was level 3. The area was reported as unaffected.

So, in general, there have been disruptions to the microchip production process, although in many cases there is no direct damage to the plants, which will still need to be restored to optimal operating conditions, restoring sterile conditions.

How is the situation locally?

After this morning’s earthquake, the local science park and Taiwan electronics factory all initiated response procedures as soon as possible, carried out necessary personnel evacuations and equipment inspections, and followed up afterwards. According to various local media sources, the extent to which major electronics manufacturers are currently affected is as follows:

Manufacturing leader, TSMC:

TSMC told the Science and Technology Innovation Board Daily reporter today that to ensure the safety of personnel, appropriate preventive measures have been initiated in accordance with the company’s internal procedures, and some areas of the factory have been evacuated. At present, all staff are safe and have begun returning to work one by one. Details have yet to be confirmed.

TSMC’s plant design is mainly Grade 7. Currently, some quartz tubes are broken, and wafers on the line are partially damaged. Some machines have been suspended for shutdown inspections to avoid detours; TSMC’s bamboo and nanke production lines have been temporarily shut down to assess damage.

At present, plant conditions appear normal. Due to safety considerations, it was decided to halt construction at factories in various parts of Taiwan today, and construction of plants underway will not be resumed until safety inspections are carried out. TSMC is building the Baoshan and Kaohsiung plants in Hsinchu, and there are also ongoing projects for advanced CoWoS packaging. It remains to be seen whether the future will affect installation progress.

Based on the current situation, the company estimates that the number of working hours affected by TSMC was less than 6 hours, impacting TSMC’s second quarter financial estimates by about US$60 million. The impact on second quarter gross margin was estimated at less than 0.5 percentage points, and the overall impact was small. Kudos to those who designed plants and emergency operating procedures.

Micron, the leader in memory chips:

Operations and supply chains after the earthquake are being evaluated; all employees are safe. Micron’s DRAM production in Taiwan accounts for about 60 percent of the company’s total DRAM production capacity.

UMC semiconductor wafer factory:

Bamboo and Nanke personnel have been evacuated in accordance with operational standards. All personnel are safe , factory facilities were in normal condition, some equipment has been shut down, and engineers are working to take stock of the situation and restore aircraft.

Semiconductor wafer manufacturer, LSMC:

Factory personnel were evacuated, all personnel were safe, and some machines were stopped as a precautionary measure. The exact impact is still being assessed.

Tokyo semiconductor equipment company Weili Technology Innovation (TEL):

The company has four plants in Taiwan and confirmed that its buildings were slightly damaged, There are no problems in the long term employees are safe.

Semiconductor wafer supplier Global Crystal:

Currently, plant and equipment engineers are checking the condition of all facilities one by one.

Without wishing to go on with the list of microchip and advanced electronics factories, it is safe to say that the excellent design, with earthquake-resistant regulations, and the application of procedures for emergency situations mean that damage will be limited and, in general, limited to the loss of a few hours of work per factory.

An example we all should follow

Although the figures are not yet final, there are reports of nine deaths and more than nine hundred injuries from a 7.3–7.4 magnitude earthquake, which, frankly, although tragic, is a small number for the magnitude of the earthquake, and this demonstrates the quality and innovation used in the implementation of civil and industrial construction in Taiwan.

The production system also proved to be incredibly robust in the face of such a natural disaster. In Europe we use the words “Resileinza” haphazardly, while in Taiwan, this term was applied in practice with intelligence and skill, and this made it possible to limit the damage, including economic damage, resulting from the earthquake.

A case where it is better to use fewer words and do much more deeds.